Custom Products

In addition to our standard products, Diamond Systems designs and manufactures custom PC/104 modules and baseboards. Often, product designers will turn to PC/104 to prototype a new product design because of its compactness, ruggedness, ease of use, open architecture, and compatibility with existing PCs.

However, every customer's requirements are different, and although our boards are designed to satisfy the majority of applications, there are instances when the combination of features you need may not be available, or they may require you to use multiple boards that may not be cost effective for volume production. Also, project requirements frequently evolve over time. At the initial stages, off-the-shelf components are satisfactory, but as the final product configuration becomes clear, you may need something else. This is the time to consider a custom product design.

Types of Custom Products

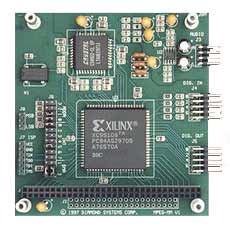

At Diamond Systems, we focus on two opportunities for custom product design: PC/104 modules and baseboards. The preferable option depends on your requirements. A custom PC/104 module is for those applications where the desired features can all fit onto the compact form factor of PC/104. For example, if you need 32 analog inputs on one card, that can usually fit on one module. A custom baseboard, on the other hand, is for those applications which require a lot of I/O and have room to allow a larger board. These applications usually involve mounting a PC/104 format CPU module onto the custom baseboard. In this alternate configuration, the I/O is the "main" board in the system, and the CPU is a "component" that mounts on top of the I/O board. For example, if you need 6 serial ports and 48 digital I/O lines, you'll probably find that a custom baseboard is the best option.

|

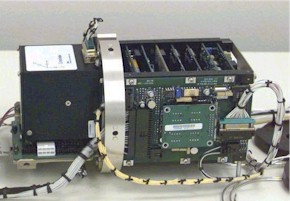

This assembly comprises the avionics for a military unmanned airborne vehicle. The right side contains an 8-board PC/104 stack consisting of 2 standard, 2 semicustom, and 4 full custom boards, along with 3 additional full custom boards mounted along the sides.

|

Benefits of a Custom Product from Diamond Systems

By using a custom product, you will obtain the following benefits:

Increased compactness |

A single module will reduce the space needed in your enclosure. |

Increased reliability |

A single module means less components to handle during manufacturing and less chances for errors during installation. |

Reduced cost |

In addition to the obvious cost savings of using a single module instead of two or three, you also benefit from reduced installation time, reduced reserve material inventory, and reduced internal product support requirements. |

Extensive experience in analog and digital I/O design |

We've been designing analog and digital I/O boards for 10 years, including ISA and PC/104 boards as well as proprietary systems. Today we have one of the broadest selections of PC/104 analog I/O modules available and are continuously expanding our product line and building up our expertise. Extensive experience in PC/104 design Diamond Systems is one of the original members of the PC/104 Consortium and was the first company to produce a line of data acquisition modules for PC/104. |

Reduced overhead |

Developing a custom I/O board in-house involves internal engineering, purchasing, manufacturing, and management resources that are always in short supply. |

Increased competitiveness |

By outsourcing your product design to Diamond Systems, you can focus your company resources more tightly on your core competencies to retain your competitive advantage. |

Reduced time to market |

We have the systems in place to design, prototype, produce, and test your custom product. We can usually provide first articles within 6 weeks from approval of specification. While this lead time is usually the most cost effective, it can be reduced by expediting various stages in the development process. |

8 Steps to a Custom Solution

- 1. Discussion of user needs

- The first step in any custom program is a clear understanding of the user's needs. This usually includes the feature set, such as how many and what type of I/O points, which features are programmable and which are fixed, etc.; physical requirements, including I/O connector and cabling types, enclosure dimensions, and environmental issues; and other general requirements.

- 2. Formal specification

- The next step is to reduce the general requirements to a formal specification that describes in detail the exact board size, location and type of I/O headers, I/O features, bus interface, and even key components. At this point a formal order is placed to Diamond Systems for the custom development.

- 3. Schematic design and review

- From the specification a circuit schematic is created to implement the required design. Interaction between the customer and Diamond Systems Engineering will ensure that all details are implemented to the satisfaction of both parties.

- 4. PCB layout and review

- After the customer approves the schematic, the next step is to create a circuit board layout. We encourage customer review of this step of the process as well.

- 5. Prototype manufacturing and assembly

- The next step is to product a prototype circuit board, purchase components, and manufacture the prototype assemblies.

- 6. Prototype test

- In most instances, the customer does most of the testing in-house to verify that the product works as expected, and also to get used to working with the product. We can provide additional testing to whatever level of completeness you require, from simple functional test to full performance testing under environmental extremes.

- 7. Prototype signoff & engineering documentation generation

- As a standard part of the process we provide you with full engineering documentation, including schematics, PCB manufacturing files, bill of material, approved vendor list, and assembly documentation.

- 8. Mass production

- Whatever volume and schedule you need, we can match it. Our assembly house, located in the heart of Silicon Valley, provides manufacturing services ranging from small prototype runs and consignment kits to high-volume full-turnkey production for Fortune 500 companies. Call Diamond Systems today to discuss your embedded systems application and see how we can be a valuable partner to you.

|